While collecting samples and analyzing the seafloor, we are also developing and testing the corer that will eventually be used on the project’s ROV to drill the coralligenous in its native environment. This work is carried on by the researchers at the University of Calabria.

Panoramic view of a blok of the calcareous tufa

Comparison between a coralligenous sample (left) and a calcareous tufa sample (right). Note the similar framework of the two samples despite the different origin of the materials.

To avoid testing the drill on the precious coralligenous samples, the drilling test is performed on calcareous tufa (selected for its geomechanical similarity with the coralligenous). The area selected for the collection of the samples is «Pietra Gna’zzita» near the Longobucco village (Calabria, Italy).

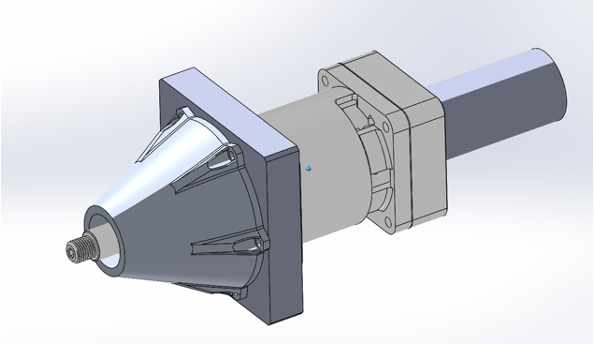

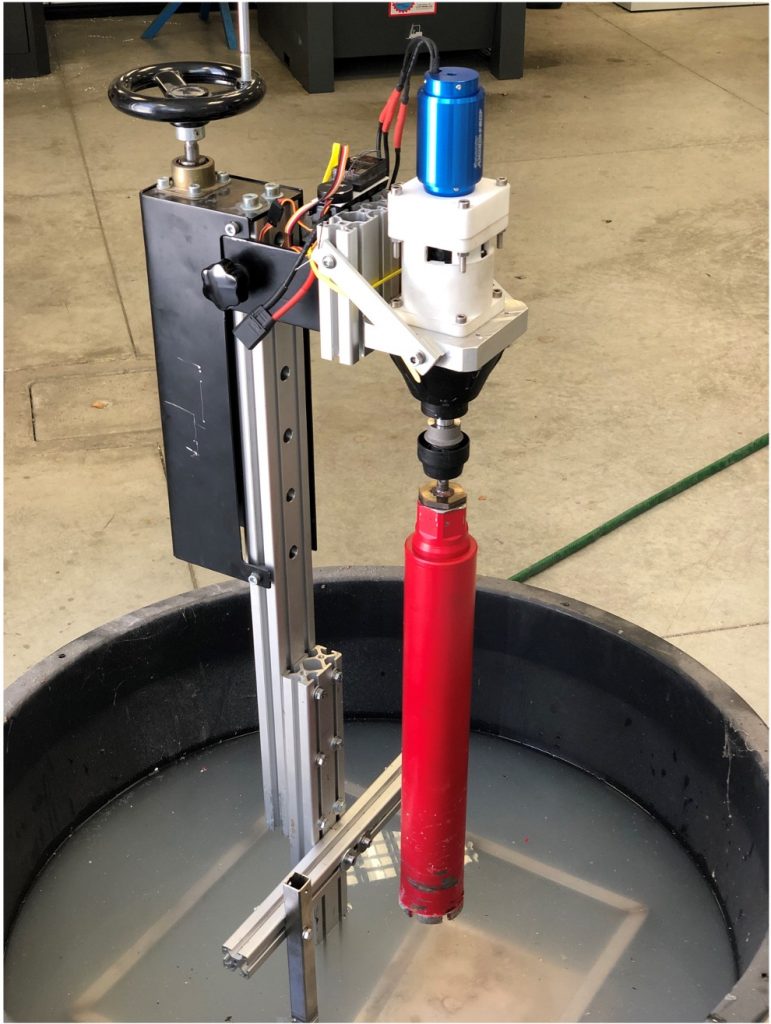

The prototype consists in a brushless gearmotor (with two speed ratio) manufactured by 3D printing technologies (plastic and metal) mounted on a linear slider fixed on a stainless-steel frame.

The test bench is designed to simulate drilling in a controlled environment (the water tank), using a 63mm diamond core drill. Several tests allow to evaluate the operating parameters of the coring system (rpm, feed rate, etc.) and the mechanical resistance of samples characterized by large cavities. A wi-fi interface has been used to monitor the motor control unit and record log data.

Corer Unit in water tank, with the 63mm diamond core drill

Sample 1: homogenous calcareous tufa

Sample 1: core D 55 mm x L 300 mm (collected in 2 steps to verify core breaking procedure)

The results allow to measure the optimal operating parameters to identify the requirements of the system and optimize the design process of the mechatronic platform to be installed on the ROV.